Smith's Paving Brick Sealer™ is an excellent sealer for any porous mineral surface. I think it's the best on the planet. I'm Steve Smith, the chemist here, and I developed this clear ultraviolet-resistant finish that permanently seals porosity and bonds to cured concrete, paving brick, porous tiles or any other mineral surface I have yet to find. I am really excited about the clear appearance and lack of yellowing, even after ten years in the weather.

It is a two-component polyurethane, 100% acrylic-free™, based on our long-lasting wood finishes. Coverage varies depending on the porosity of the surface. A smooth-troweled concrete garage floor, for example, will only absorb about a gallon for 400 square feet, while some paving bricks absorb about twice that. Thus, the cost to a contractor sealing such surfaces is about twenty-five to fifty cents per square foot. We manufacture it, and can ship it to your jobsite.

We expect to only sell you this product once, so we designed it to last longer than what you put it on. This sealer is based on our Five Year Clear™ polyurethane coating technology for wood, which lasts more than five years on wood directly exposed to the sun. This is not another water-emulsion acrylic sealer. They break down in a few years of sunlight, and biodegrade in a few years of dark and damp. This is a two-component polyurethane, guaranteed 100% acrylic-free.

The new concrete sealer was developed from our Five Year Clear™ technology by toughening the resin system so it was strong enough to glue together the sand grains between paving bricks, increasing the moisture tolerance and accelerating the curing speed so one application would be substantially cured overnight, and reducing the viscosity so one application would penetrate the microscopic porosity of concrete paving stones or poured concrete slabs in a few seconds.

Oil-staining will be a thing of the past, with detergent cleaners now able to remove dark oil stains which can no longer penetrate. Efflorescence will be a thing of the past. Here's actual experimental results:

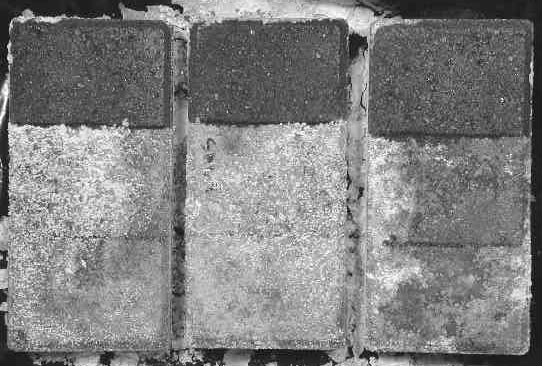

These paving stones were efflorescence-stained from damp storage when new. The upper 2/3 of each was cleaned with acid to remove the efflorescence, and the upper 1/3 coated with Smith's Paving Brick Sealer™.

The variation in efflorescence represents the actual variation in porosity of randomly-chosen paving stones. The initial efflorescence did not return, and there is a complete blocking of efflorescence from evaporating saltwater in the treated areas. Smith's Paving Brick Sealer is effective on paving stones of low, medium and high porosity.

COVERAGE FOR VARIOUS SURFACES

On a concrete surface a single quart may be sufficient for 100 square feet,

which is 400 sq. ft. per gallon. On some more porous concrete or some paving stones, the surface may absorb more material, to 50

square feet per quart or even less. This is equivalent to 200 square feet per gallon.

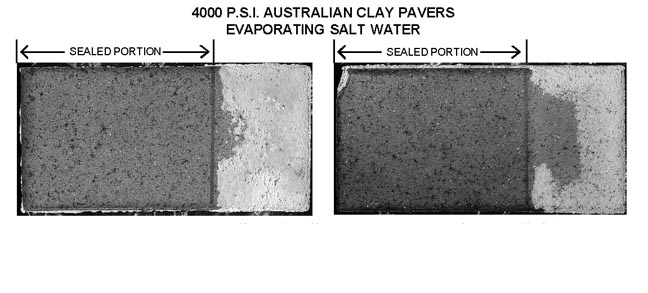

This product has been tested on a red an

orange paving brick, 4cm thick, about 4” x 8”, commonly known as 4000 p.s.i. Australian Clay Pavers. The red brick

absorbed enough to give a coverage of 140 square feet per gallon. The orange brick absorbed even more, giving a coverage of 100

square feet per gallon. This is indicative of a depth and degree of porosity, and more might have soaked in if more were applied.

In order to obtain the most cost-effective results, apply the material by roller (with broom-handle extension) uniformly over a

surface, budgeting equal portions over identical (marked-off) areas.

It should not be necessary to apply more than 1 quart per

50 square feet. The idea is to seal the surface uniformly, not necessarily at great depth. If in doubt, attempt a second application

within an hour. Do not leave excess liquid standing on the surface.

APPLICATION PROCEDUREE

Add catalyst to base container. Follow instructions on catalyst container.

Shake well to mix thoroughly. Pour into a roller tray and apply to the concrete floor, driveway, etc., or paving stones.

Ensure

that sealer flows into all spaces between paving stones by applying twice, in two perpendicular directions.

The final gloss may be reduced so as to make the cured sealer less conspicuous

by brushing a dry flatting agent over the surface while the liquid film is still wet, or by adding a liquid flatting agent to a

second coat.

Before sealing a large area, test a small area with a small portion, to ensure you know what appearance to expect.

We do not expect the cured sealer to be removable from any surface with any chemical stripper, nor any mechanical means short of sandblasting.

© copyright 1972 - 2016, Steve Smith, reprinted with permission